In the last ten years, space organisations globally, along with new market players, have made it easier to access space for scientific and technological research. This movement towards making space more accessible has attracted a broader spectrum of scientists who were previously unaware of the possibilities for conducting experiments in space. This growing group includes experts from various fields such as biology, physiology, pharmaceutical chemistry, fluid physics, soft matter, and thermodynamics, although this list is far from complete.

However, many researchers from this broadened community may not completely grasp the intricate requirements for setting up and carrying out space experiments. CRESTLAB has been established to provide an extensive research platform to assist both academic and industrial sectors in designing, preparing, and performing benchmark experiments on Earth, which can then be modified for different space environments—whether it be in microgravity, lunar or Martian gravity, or hyper gravity.

CRESTLAB is structured around four specialized laboratories—Life Sciences, Material Sciences, Physical Sciences, and Data Science—along with two technical workshops. These facilities boast advanced instruments and support services that cover all phases of space experiment planning, from the initial engineering design and breadboard construction to early testing and data analysis.

Along with the technical support offered by our experts at CREST, here is a list of some major equipment available at CRESTLAB to help design space experiments:

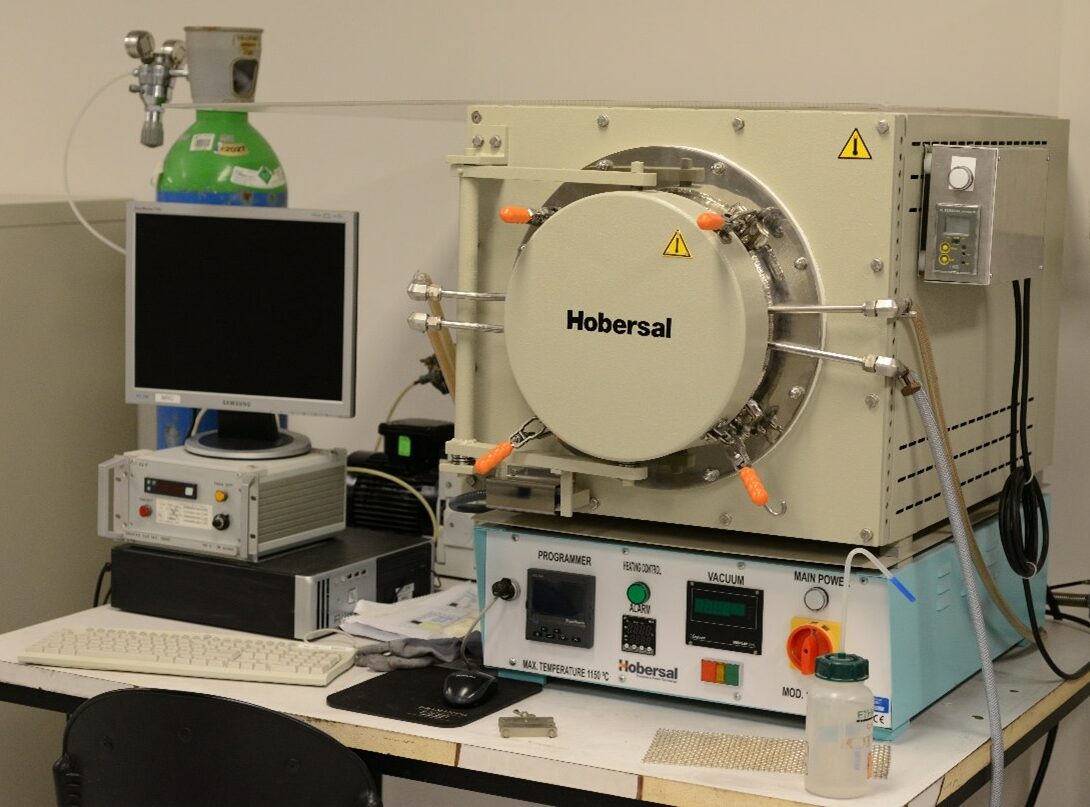

Vacuum and controlled atmosphere chamber furnace 15PR400V PAD P

Brand: HOBERSAL

Description: HOBERSAL Furnaces For Metal and Ceramic 3d Printing Processes and Additive Manufacturing. Ceramic and metal Sintering, Annealing, debinding, fusing, curing. Works under vacuum and controlled atmosphere to ensure the sintered part is not contaminated by oxygen.

Applications:

Metals sintering: Debinding, sintering, stress-relieving, solution annealing and hardening

Ceramics, Glass, Composites, Sand sintering: Debinding, sintering, drying and curing

Plastics sintering: Curing, tempering, drying

Temperatures 1.150 ºC

Characteristics:

- Electronic-valve equipment to control gas atmosphere or/and vacuum.

- Eurotherm programmable controller equipment (10 programs/25 segments) with alarm (Over-heating Protection)

- Eurotherm programmable controller EPC Series and data logger software

- This system enables complete automatic electronic programming and controlling of the furnace chamber’s atmosphere, with automatic gas introduction, replacement and/or extraction.